Application

Aluminum raised floors can be used in the following fields: microelectronics industry (wafer plant, TFT/LCD, packaging and testing, printed circuit boards), semiconductor industry, flat panel display industry, optoelectronics, life science industry, precision engineering and ultra-clean environmental electronics industry.

Characteristics

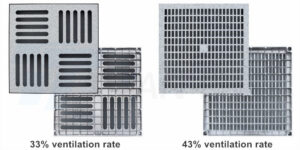

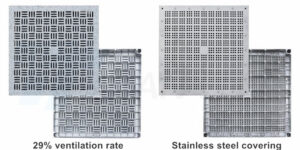

- 17%-43% ventilation rate

- Patent design with high dimensional accuracy

- Light weight and excellent loading capacity

- Conductive and static dissipative coverings and coatings

- Contains no ferrous materials to disrupt magnetic fields

- Excellent rolling load performance

- Die cast aluminum panels meet call A1 fire rating

- Good performance of waterproof

- Pollution and radiation free

- Recyclable and economic system

- Various pedestals and structure system.

Edge trim

Four edges of panels can be grooved by milling machine, insert PVC edge trim to protect the floor coverings. Refer to below image, left one is trimless type, right one is PVC edge trim type.

Corner connection

In places with high stability requirements, panels can be connected to the understructures with corner lock holes. Refer to below image, left one is free standing system type, right one is corner lock system type.

Damper

Damper can realize free adjustment of ventilation rate, adjustment range is from 0 to panels’ fixed rate. Left one is steel material damper, and right one is aluminum material damper.

Reviews

There are no reviews yet.